Bosch Packaging Technology, in co-operation with Spee-Dee, launched a duplex packaging solution for ground coffee. The combination of a Spee-Dee auger filler and a Bosch vertical bagger produces up to 300 high-quality fractional coffee bags/min with a maximum bag width of 7 in. on minimum floor space.

The cost-effective design supports product and material waste reduction, while simplifying cleaning and maintenance. Butter Packaging Machine

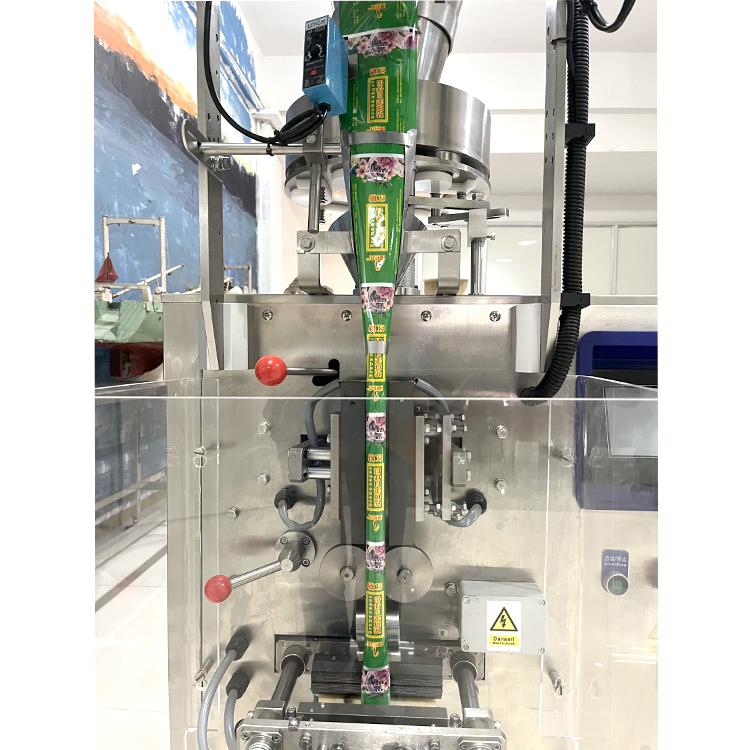

Spee-Dee’s 3600 Twin auger filler and Bosch’s SVE 1820 MR continuous motion bagger combine to make this duplex machine fit on just 36.6 sq-ft (3.4 square meters), doubling the output on a fraction of the production space.

To protect the ground coffee, the Spee-Dee auger filler offers high filling accuracy through tendency regulation with a checkweigher and thus cuts product waste. It also features a patented sliding key tooling lock for effortless changeovers, while a single hopper inlet simplifies the upstream product delivery system. The open vertical form, fill and seal (VFFS) machine design makes cleaning, maintenance and monitoring easy, improving overall equipment effectiveness.

Automatic Packaging Machine No matter if ground coffee producers need to switch from decaf to regular or flavored coffee, tool-less hopper changeovers reduce downtime and minimize cross-contamination risk. Customers also profit from the optional nitrogen flushing feature, which extends the product’s shelf life. Furthermore, the high-quality seals work with various film materials – coffee producers can choose between two- and three-ply films without compromising on sealing quality.